Manufacturing method

We have been producing rigid polyvinyl chloride since 1954, recognizing its excellent workability, chemical resistance, and cost-effectiveness. Over half a century of experience has enabled us to accumulate a wealth of expertise. Throughout this time, we have focused on enhancing product quality and functionality, introducing products with high heat resistance, chemical resistance, flame retardancy, and impact resistance to the market. With our rich experience and track record, we offer a wide range of high-quality, high-performance products.

-

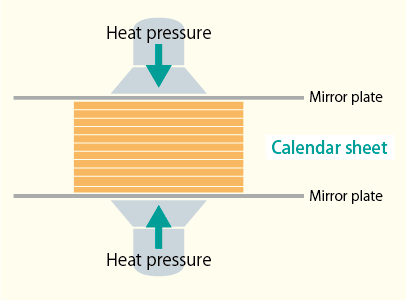

Calendar Press Method

We laminate 0.5mm calendar sheets and mold them into sheets using heat and pressure.

-

Extrusion Process

The material is extruded through a die via an extruder, then passed through rollers for thickness control and surface finishing.

-

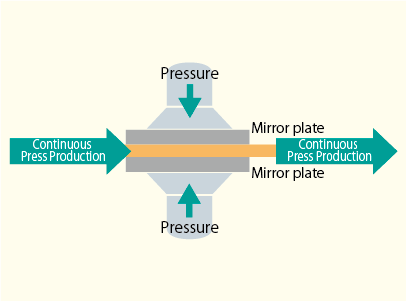

Continuous Press Method

We utilize a combination of pressing and extrusion methods, retaining the advantages of both techniques.

Product Features and Manufacturing Methods

| Manufacturing Method Product Features | Pressing Method | Extrusion Method | Continuous Pressing Method |

|---|---|---|---|

| You can obtain products with a pleasing appearance. | 〇 | △ | 〇 |

| There is minimal difference in vertical and horizontal expansion during heating. | 〇 | × | 〇 |

| We can produce products with custom lengths. | × | 〇 | 〇 |

| There is minimal shrinkage due to heat. | × | △ | 〇 |

Takiron CI Factory Introduction Video

Let us briefly introduce the unique manufacturing methods of our plate products.