Processing method

-

1Machining

It is a processing method to change the shape of plastic by using machines such as cutting, drilling, punching, and cutting.

When cutting, milling, or drilling, the following points should be considered to obtain a clean finish without chips or cracks.

(1) The most important point in machining is to use tools with good sharpness.

(2) Prevent temperature rise due to heat generation during machining.

(3) Control the working temperature to prevent cracking during machining, especially in winter.

(4) When shearing or punching, select a blade clearance appropriate for the thickness and shape of the plate.

(5) Use an appropriate window plate or underlay to prevent chipping.

If the clearance between the window plate and the saw blade on the elevating circular sawing machine or running saw is too large, replace the window plate. When punching with a Thompson blade, replace the underlay when the groove at the blade contact is enlarged. When drilling with a drill, use of a carpet pad is recommended. -

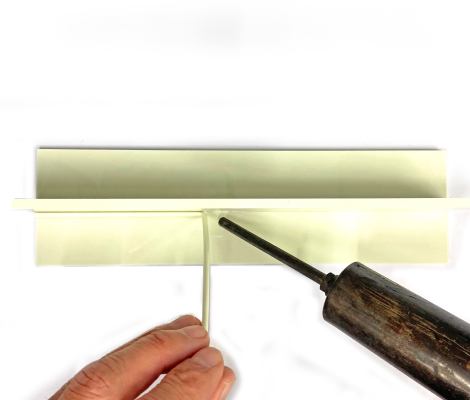

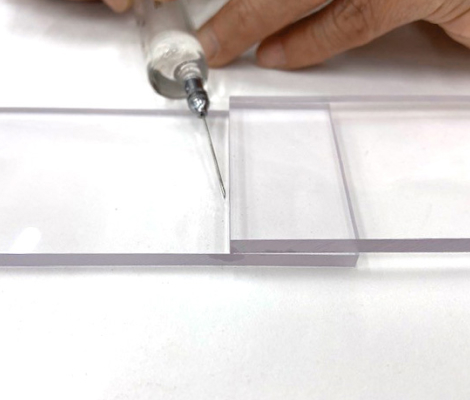

2Adhesive processing

This is a processing method in which Takibond (solvent type) is poured onto the bonding surface using a syringe to melt the plastic and bond it evenly.

Adhesion of multiple Takiron plates To bond multiple Takiron plates, use Adhesive No. 200 (solvent type). Adhesive No. 200 is particularly practical since it can be applied with syringes.

Instructions for Adhesion Processing

(1) Do not use more adhesive than necessary.

(2) Work fast and do not move the plates until the adhesive has properly dried.

(3) Avoid separating and reattaching the plates once they have been bonded. Doing so will weaken the adhesive significantly.

(4) Reinforce the corners with adhesive rods to increase the adhesion surface and prevent cracking that can occur due to stress concentration.

(5) Adhesive spills may leave marks in the material. Exercise caution during work. In particular, be sure to take the necessary steps to ensure fire safety and adequate ventilation when performing adhesion processes.

-

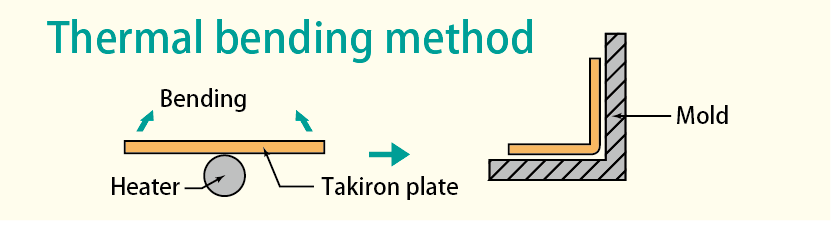

3Thermal Processing

Takiron plates become soft when heated, making them easy to bend or mold into various shapes. This method enables shape modification by cooling after heating.

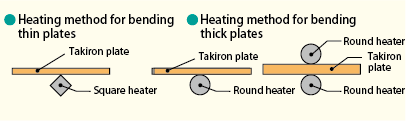

● Bending

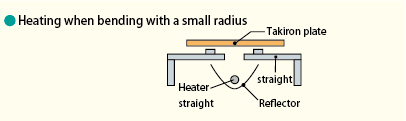

Takiron Plates can be easily heated and bent using standard rod heaters, which are available in square and round types. For sheets with a thickness of 2 mm or less, the edge of a square heater is recommended, while a round heater works best for thicker sheets. Additionally, Applying Teflon tape to the heater's surface can prevent adhesion during heating, ensuring a clean, smooth bend.

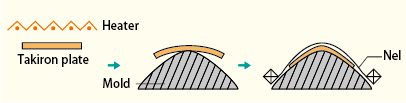

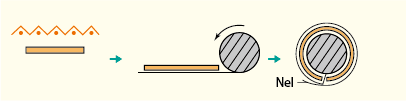

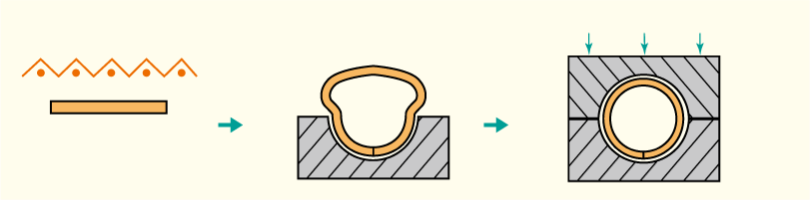

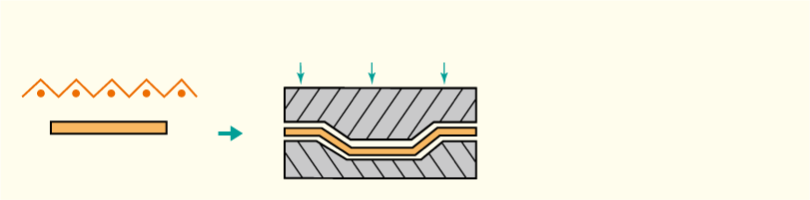

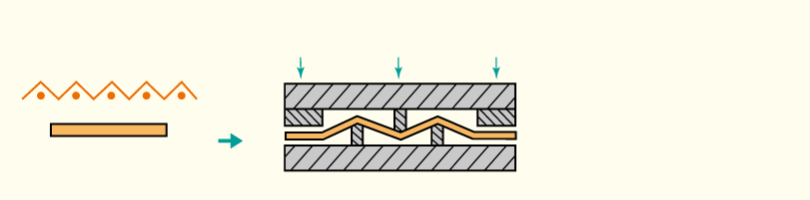

● R-bending and forming

It is necessary to devise processing and forming methods according to the shape and quantity each time, but the basic method is as follows. Please note that lower temperatures tend to produce a cleaner finish. Additionally, since the material shrinks during free heating, plan your cutting accordingly. Furthermore, in the case of using press plates, please be aware that surface roughness phenomena are likely to occur.

-

4Welding process

Using a hot-jet welding machine, the base metal and welding rod are heated and melted, and then pressed together to form a single piece.